MORESCHI’S FRICTION SAW BLADES

The friction saw blades are used to cut billets, tubes, slabs and grates. They are called friction because the cut is done thanks to the friction between the teeth of the blade and the working material.

Our saw blades are manufactured from hot rolled steel sheet in chromium-wanadium 1.2235 or wolfram-molybdenum 1.2604 choosing the hardness according to the temperature and the type of the material to be cut.

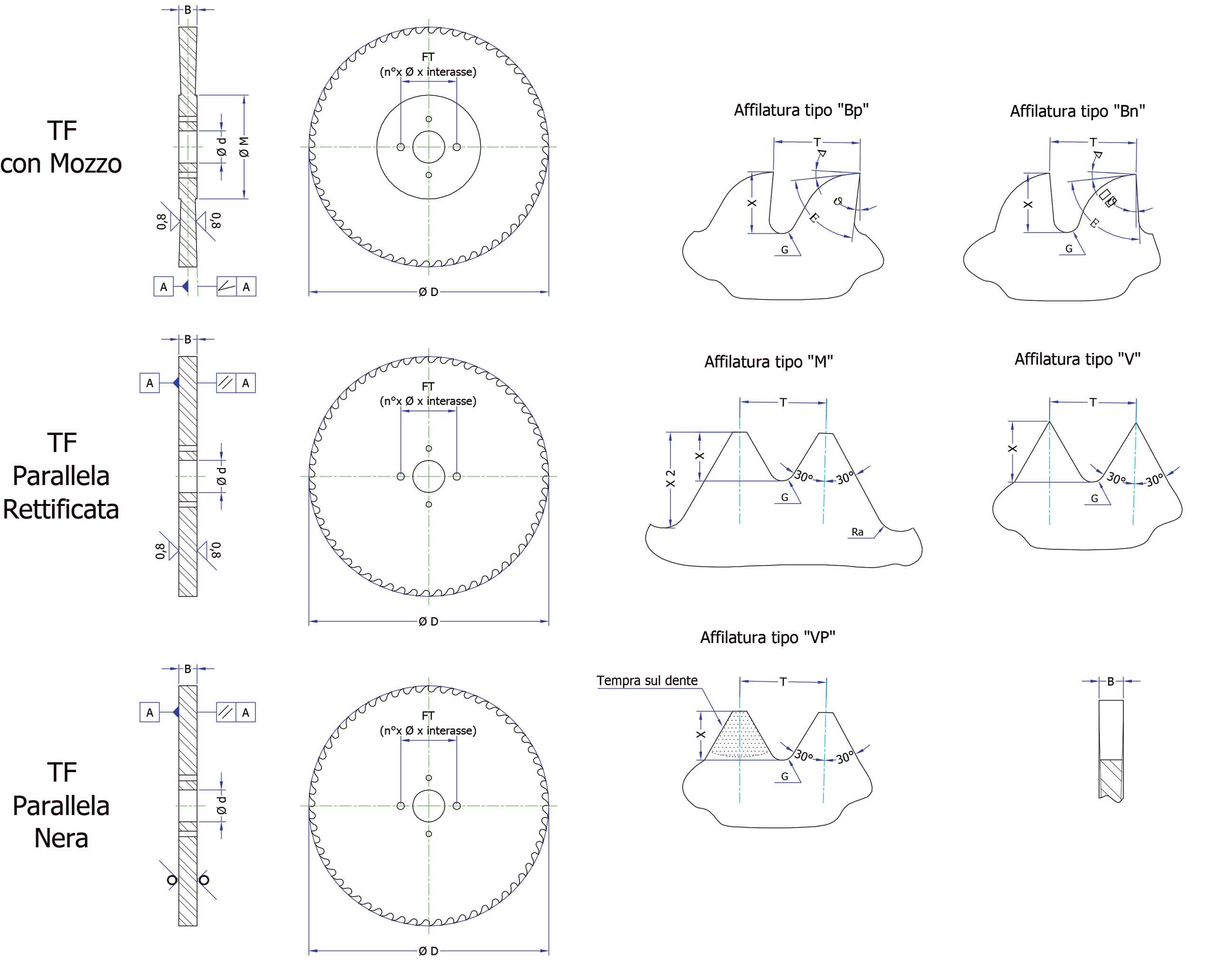

We can supply saw blades hardened all over, on the external belt or on the teeth tips. The flanks can be grinded: tapered with hub, straight or left black as hot rolled.

The “secret” for the optimization of the cut with friction saw blades is finding the right balance between the saw hardness and the combination hardness/temperature of the material to be cut.

Moreschi uses successfully specific tooth form accordingly with the type of material and the cutting conditions

| Simbolo / Symbol | Descrizione / Description |

|---|---|

| Ø D | Diametro lama/ Saw blade diameter |

| B | Spessore di taglio / Kerf |

| Ø M | Diametro mozzo corpo lama / Diameter of the hub |

| D | Diametro foro centrale / Bore diameter |

| FT | Fori di trascinamento (n°x d x PCD) / Pin-holes (n°x d x PCD) |

| Z | Numero di denti / Number of teeth |

| T | Passo dei denti / Teeth pitch |

| BP | Dente affilato a Becco di civetta positivo / Parroth tooth positive |

| BN | Dente affilato a Becco di civetta negativo / Parroth tooth negative |

| V | Dente a forma di V / V sharpening tooth |

| VP | Dente a forma di V smusso piano / V sharpening tooth flat bevel |

| M | Dente a forma di M smusso piano / M sharpening tooth flat bevel |

| Foro centrale Bore | Ø M mm. | Fori di trascinamento Pin holes |

|---|---|---|

| 40 | 220 | 2/12/64 |

| 50 | 220 | 2/16/120 |

| 60 | 250 | 4/16,5/200 |

| 70 | 250 | 4/19/180 |

| 80 | 200 | 2/16/140 |

| 85 | 250 | 4/16,5/210 |

| 100 | 220/250 | 2/13/160 |

| 120 | 300 | 4/17/180 |

| 160 | 400 | 4/26/260 |

| 175 | 400 | 4/26,5/250 |

| 180 | 500 | 2/30/260 |

| 200 | 350 | 2/26/400+2/26/260+2/22/300 |

| Materiale / Material | Vc (m/min) | Troncatura Profili e Pieni Vf (mm/min) Profiles and solids cut-off |

|---|---|---|

| Acciaio al carbonio Carbon steel | 6000 ÷ 8400 | 80 ÷ 2000 |

| Acciai inossidabili AISI 304 ÷ 316 Stainless steel | 5400 ÷ 7500 | 1400 ÷ 2000 |

It is important for the good operation of the friction and hot saw blades that the debris of the work materials are removed from the gullets of the teeth using high pressure jets of coolant at the exit of the cutting zone.

Please note that the recommended cutting parameters are only general indications and they must be adjusted depending on cutting conditions, sawing machine conditions and the material to be cut. Our technical department is available to help you finding the most suitable parameters for each particular application.

| D. | B | Z. | T | d. | |

|---|---|---|---|---|---|

| 300 | 2,5 | 200 | - | 4,7 | 40 |

| 3,0 | 200 | - | 4,7 | 40 | |

| 350 | 2,5 | 200 | 220 | 5,5 | 40 |

| 3,0 | 200 | 220 | 5,5 | 40 | |

| 400 | 2,5 | 240 | 300 | 5,2 | 40 |

| 3,0 | 240 | 300 | 5,2 | 40 | |

| 4,0 | 240 | 300 | 5,2 | 40 | |

| 450 | 2,5 | 240 | 300 | 5,9 | 40 |

| 3,0 | 240 | 300 | 5,9 | 40 | |

| 4,0 | 240 | 300 | 5,9 | 40 | |

| 500 | 3,0 | 300 | - | 5,2 | 40 |

| 4,0 | 300 | - | 5,2 | 40 | |

| 5,0 | 300 | - | 5,2 | 40 | |

| 6,0 | 300 | - | 5,2 | 40 | |

| 520 | 3,0 | 300 | - | 5,4 | 40 |

| 4,0 | 300 | - | 5,4 | 40 | |

| 5,0 | 300 | - | 5,4 | 40 | |

| 6,0 | 300 | - | 5,4 | 40 | |

| 550 | 3,0 | 300 | - | 5,8 | 40 |

| 4,0 | 300 | - | 5,8 | 40 | |

| 5,0 | 300 | - | 5,8 | 40 | |

| 560 | 3,0 | 300 | - | 5,9 | 40 |

| 4,0 | 300 | - | 5,9 | 40 | |

| 5,0 | 300 | - | 5,9 | 40 | |

| 6,0 | 300 | - | 5,9 | 40 | |

| 580 | 4,0 | 300 | - | 6,1 | 40 |

| 5,0 | 300 | - | 6,1 | 40 | |

| 6,0 | 300 | - | 6,1 | 40 | |

| 600 | 4,0 | 300 | - | 6,3 | 100 |

| 5,0 | 300 | - | 6,3 | 100 | |

| 6,0 | 300 | - | 6,3 | 100 | |

| 650 | 4,0 | 240 | - | min 6,0 | 100 |

| 5,0 | 240 | - | min 6,0 | 100 | |

| 6,0 | 240 | - | min 6,0 | 100 | |

| 700 | 4,0 | 240 | - | min 6,0 | 100 |

| 5,0 | 240 | - | min 6,0 | 100 | |

| 6,0 | 240 | - | min 6,0 | 100 | |

| 7,0 | 240 | - | min 6,0 | 100 | |

| 750 | 5,0 | 240 | - | min 6,0 | 120 |

| 6,0 | 240 | - | min 6,0 | 120 | |

| 7,0 | 240 | - | min 6,0 | 120 | |

| 800 | 5,0 | 260 | - | min 6,0 | 120 |

| 6,0 | 260 | - | min 6,0 | 120 | |

| 7,0 | 260 | - | min 6,0 | 120 | |

| 8,0 | 260 | - | min 6,0 | 120 | |

| 850 | 6,0 | 260 | - | min 6,0 | 120 |

| 7,0 | 260 | - | min 6,0 | 120 | |

| 8,0 | 260 | - | min 6,0 | 120 | |

| 900 | 7,0 | 260 | - | min 6,0 | 120 |

| 8,0 | 260 | - | min 6,0 | 120 | |

| 950 | 7,0 | 260 | - | min 6,0 | 120 |

| 1000 | 7,0 | 400 | - | min 6,0 | 175 |

| 7,5 | 400 | - | min 6,0 | 175 | |

| 8,0 | 400 | - | min 6,0 | 175 | |

| 10,0 | 400 | - | min 6,0 | 175 | |

| 1200 | 9,0 | 400 | - | min 7,0 | 175 |