MORESCHI’S SEGMENTAL SAW BLADES

The segmental saw blades ere used to cut ferrous and non ferrous metals, billets, tubes, profiles and bars.

The segmental saw blades are made using segments made of hardened HSS steel grade M2-1.3343 riveted on Cr-V steel blanks.

The use of segmental saw blades is economically convenient because if some teeth are broken the segment can be replaced and re-sharpened as usual.

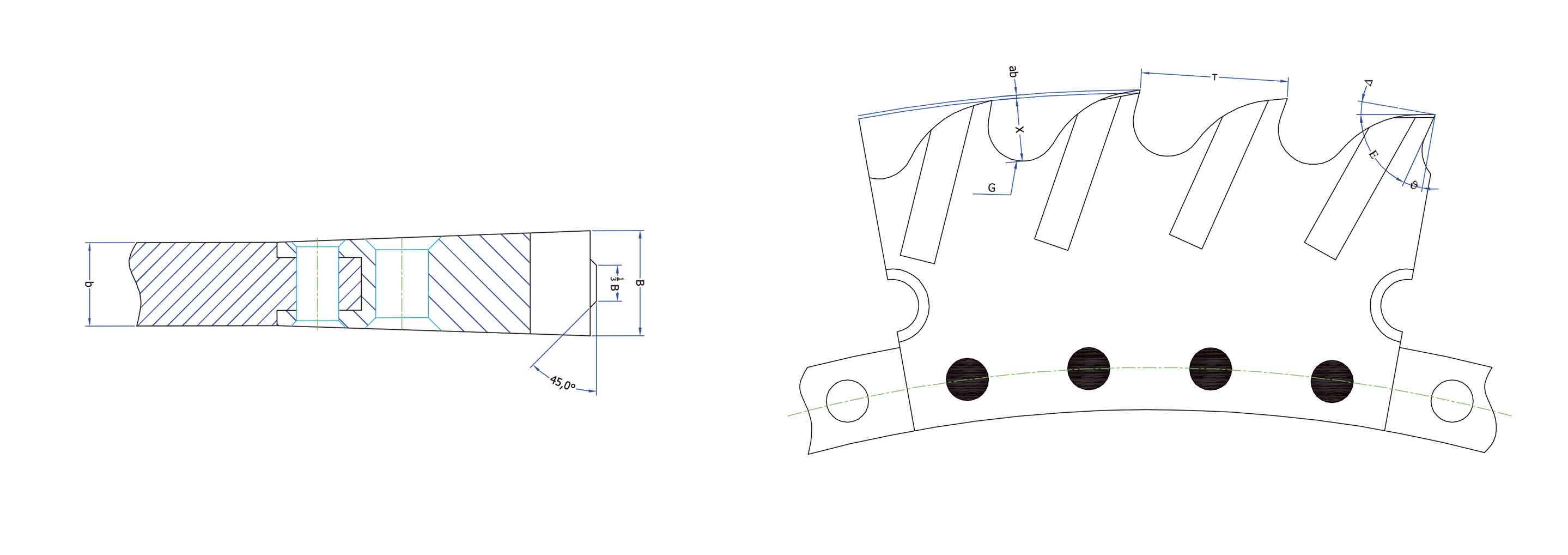

| Simbolo – Symbol | Descrizione - Description |

|---|---|

| Ø D | Diametro lama / Saw blade diameter |

| B | Spessore di taglio / Kerf |

| B | Spessore del corpo / Body thickness |

| Ø d | Diametro foro centrale / Bore diameter |

| FT | Fori di trascinamento (n°x d x PCD) / Pin-holes (n°x d x PCD) |

| T | Passo dei denti / Teeth pitch |

| TV | Passo dei denti Variabile / Variable tooth pitch |

| X | Altezza del dente / Tooth height ( T x 0,45 ) |

| ab | Differenza altezza denti HZ / Tooth height difference (ab=0,20÷ 0,30 ) |

| g | Angolo di taglio / Rake angle |

| a | Angolo di spoglia / Clearance angle |

| gV | Angolo di taglio Variabile / Variable rake angle |

| G | Raggio gola dente / Gullet radius ( G = T x 0,25 ) |

| Hh | Fori di sollevamento / Handling holes |

The BW shape is used to cut tubes and profiles

The HZ shape is used to cut solid bars and tubes / profiles with high wall thickness

The BS shape is used to cut tubes with low or medium wall thickness.

| Materiali Materials | Angoli di taglio | Angolo di spoglia |

|---|---|---|

| Acciaio / Steel 350 ÷ 900 N/mm2 | 20 | 8 |

| Acciaio / Steel 900 ÷ 1200 N/mm2 | 15 | 6 |

| Acciaio inossidabile / Stainless steel | 12-15 | 6 |

| Ghisa / Cast iron | 12 | 6 |

| Alluminio e sue leghe / Aluminium alloys | 30 | 12 |

| Rame / Copper | 25 | 10 |

| Bronzo / Bronze | 20 | 8 |

| Ottone / Brass | 20 | 10 |

| D. mm. | Sp. Mm | T mm. | Dimensioni mm. | T mm. |

|---|---|---|---|---|

| ≤ 1,0 | 3,0 / 3,5 | 10 ÷ 20 > 20 ÷ 40 > 40 ÷ 60 > 60 ÷ 90 > 90 ÷ 110 > 110 ÷ 130 | ||

| > 1,0 ÷ 1,5 | 4,0 / 5,0 | |||

| > 1,5 ÷ 2,0 | 5,0 / 6,0 | 5 / 6 | ||

| 10 ÷ 50 | > 2,0 ÷ 3,0 | 5,5 / 6,5 | 7/9 | |

| > 3,0 ÷ 4,0 | 6,5 / 8,0 | 10/12 | ||

| > 4,0 ÷ 6,0 | 7,0 / 8,0 | 13 / 14 | ||

| ≤ 1,0 | 13 / 15 | |||

| > 1,0 ÷ 1,5 | 3,5 / 5,0 | 16 / 18 | ||

| >50 ÷ 100 | > 1,5 ÷ 2,0 | 5,5 / 6,0 | ||

| > 2,0 ÷ 3,0 | 6,0 / 7,0 | |||

| > 3,0 ÷ 4,0 | 7,0 / 8,0 | |||

| > 4,0 ÷ 6,0 | 8,0 / 9,0 |

| Materiale / Material | Vc (m/min) Standard | Vc (m/min) PVD | fz (mm/z |

|---|---|---|---|

| Acciai basso legati ≤ 400 N/mm2 Low alloy steels ≤ 400 N/mm2 | 25-35 | 70 ÷ 95 | 0.05-0.15 |

| Acciai basso legati ≤ 600 N/mm2 Low alloy steels ≤ 600 N/mm2 | 24-28 | 60-80 | 0.05-0.15 |

| Acciai medio-legati ≤ 900 N/mm2 Medium alloy steels ≤ 900 N/mm2 | 14-25 | 40-65 | 0.05-0.15 |

| Acciai legati ≥ 900÷1200 N/mm2 Alloy steels ≥ 900÷1200 N/mm2 | 10-18 | 30-55 | 0.04-0.1 |

| Acciai inossidabili AISI 300 - Stainless steel AISI 300 | 8-14 | 15-25 | 0.08-0.15 |

| Acciai inossidabili AISI 400- Stainless steel AISI 400 | 8-14 | 15-25 | 0.08-0.15 |

| Rame / Copper | 120-250 | 500 ÷ 1000 | 0.08-0.16 |

| Ottone / Brass | 250-400 | 600 ÷ 1200 | 0.07-0.15 |

| Alluminio / Aluminium | 400-950 | 800 ÷ 1500 | 0.05-0.2 |

| Materiale / Material | Vc (m/min) Standard | Vc (m/min) PVD | fz (mm/z |

|---|---|---|---|

| Acciai basso legati ≤ 400 N/mm2 Low alloy steels ≤ 400 N/mm2 | 30 ÷ 50 | 110 ÷ 200 | 0.15 ÷ 0.28 |

| Acciai basso legati ≤ 600 N/mm2 Low alloy steels ≤ 600 N/mm2 | 24 ÷ 30 | 90 ÷ 180 | 0.15 ÷ 0.28 |

| Acciai medio-legati ≤ 900 N/mm2 Medium alloy steels ≤ 900 N/mm2 | 20 ÷ 40 | 65 ÷ 160 | 0.1 ÷ 0.2 |

| Acciai legati ≥ 900÷1200 N/mm2 Alloy steels ≥ 900÷1200 N/mm2 | 10 ÷ 30 | 40 ÷ 100 | 0.05 ÷ 0.12 |

| Acciai inossidabili Aisi 300 - Stainless steel | 10 | 15 ÷ 45 | 0.12 ÷ 0.15 |

| Acciai inossidabili Aisi 400- Stainless steel | 30 ÷ 40 | 60 ÷ 150 | 0.12 ÷ 0.15 |

| 250 | 3,5 | 2,8 | 12 | 32 4-9-50 | C | C | C | C | C | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 275 | 3 | 2,2 | 12 | 40 2-8-55+4-12-64 | C | C | C | C | ||||

| 315 | 3,6 | 3 | 14 | 40 2-11-55+4-12-64 | C | C | C | C | C | C | ||

| 360 | 3,6 | 2,8 | 16 | 40 2-11-55+4-12-64 | C | C | C | C | ||||

| 50 4-15-80+4-15-85 | C | C | C | C | C | |||||||

| 370 | 3,6 | 2,8 | 16 | 50 4-15-80+4-15-85 | C | C | C | C | ||||

| 400 | 4 | 3,2 | 16 | 50 4-15-80+4-15-85 | C | C | C | C | L | L | ||

| 425 | 4 | 3,2 | 18 | 50 4-15-80 | C | C | C | C | ||||

| 450 | 4 | 3,3 | 18 | 50 4-15-80+4-18-100 | C | C | C | C | ||||

| 460 | 4,7 | 3,3 | 18 | 50 4-15-80+4-18-100 | C | C | ||||||

| 60 8-16-90+4-18-100 | C | C | ||||||||||

| 500 | 5 | 3,8 | 18 | 50 4-15-80+4-18-100 | C | C | C | C | L | L | L | |

| 570 | 5,7 | 4 | 18 | 80 4-23-120 | C | C | C | |||||

| 80 8-22-142 | C | C | C | |||||||||

| 630 | 6 | 4 | 20 | 80 4-23-120 | C | C | C | L | L | L | ||

| 660 | 6 | 4 | 20 | 80 4-23-120 | C | C | C | C | ||||

| 80 8-22-142 | C | C | C | L | L | |||||||

| 710 | 6 | 4,5 | 24 | 80 4-23-120 | C | C | C | C | L | L | L | |

| 760 | 6 | 4,5 | 24 | 80 4-23-120+4-27-160 | C | C | C | C | ||||

| 800 | 7 | 5 | 24 | 80 4-23-120+4-27-160 | C | C | C | |||||

| 910 | 7 | 5 | 30 | 80 4-23-120+4-27-160 | C | C | C | C | C | |||

| 100 8-27-186 | C | C | C | C | C | |||||||

| 1020 | 8,3 | 6,2 | 30 | 100 4-32-200 | C | C | C | C | C | |||

| 1120 | 8,5 | 6,5 | 36 | 100 4-32-200 | C | C | C | C | C | |||

| 1250 | 9 | 7 | 36 | 100 4-32-250 | L | C | C | C | C | L | ||

| 100 4-32-220+4-32-250 | ||||||||||||

| 1320 | 9 | 7 | 36 | 100 4-32-250 | C | C | C | C | C | C | ||

| 160 8-32-270+4/42/315 | C | C | C | |||||||||

| 1430 | 9,5 | 7,5 | 36 | 100 4-32-250 | L | C | C | C | C | L | ||

| 1510 | 10,5 | 8,5 | 36 | disegno - draw | C | C | C | C | C | |||

| 1610 | 10,5 | 8,5 | 40 | disegno - draw | C | C | C | C | C |

C: Segment with cooling slots

L: Smooth segment