CIRCULAR SAW BLADES

CIRCULAR SAW BLADES

BLOG

Blade Life: Optimizing the Performance of Circular Blades

In the production cycle, the duration of blades plays a crucial role. To ensure you get the most out of your tool, it’s essential to follow some tips.

Cutting System Check

Before starting work, it’s important to carefully check your cutting system. Here are some key aspects to consider:

• Blade Housing: Ensure it is not damaged and that the clearance between the housing and the blade is minimal.

• Flanges: They must be clean and without deformations.

• Blade Guide: Adjust the blade guide so that it has minimal clearance.

• Brush: Check that the brush is in good condition (where present).

• Lubrication and Nozzle Orientation: Adjust the amount of oil based on the size of the piece to be cut, orient the nozzles on the blade’s tooth.

• Wear and Alignment of Vises: Ensure they are in good condition and correctly aligned.

Setting Parameters

In addition to checking the system, it is essential to correctly set the cutting parameters. The main parameters include:

• Cutting Speed: Expressed in meters per minute (m/min), it represents the peripheral speed of the blade.

• Number of Revolutions per Minute: The rotational speed of the blade.

• Feed Rate: Expressed in millimeters per minute (mm/min) or millimeters per tooth (mm/t), it represents the feed rate of the blade within the piece to be cut.

The choice of the right parameters depends on the blades used and the material to be cut. There are specific formulas to calculate these parameters, but it is often advisable to consult an expert. Each application can have its peculiarities, and even a small adjustment can make a difference.

Technical Support

If you have any doubts or need assistance, do not hesitate to contact our company. Our technicians are available to provide support and personalized advice.The maintenance of circular saw blades plays a crucial role in ensuring cutting quality, extending the tool’s lifespan, and reducing production costs. With over 35 years of experience in the industry, we offer some tips on when and how to intervene to keep blades in perfect operating condition.

Maintenance of Saw Blades

The maintenance of circular saw blades plays a crucial role in ensuring cutting quality, extending the tool’s lifespan, and reducing production costs. With over 35 years of experience in the industry, we offer some tips on when and how to intervene to keep blades in perfect operating condition.

When is it Necessary to Sharpen the Blade?

Knowing when a blade needs sharpening is essential to avoid issues that can compromise productivity and the quality of the finished product. Here are the main signs indicating the need for sharpening:

1. Machine Signals: Some systems are equipped with sensors that alert the operator when the blade requires excessive effort. This is a clear signal that the blade needs to be sharpened.

2. Increased Cutting Time: An increase in the time required to complete a cut compared to normal can indicate that the blade is not efficiently sharp.

3. Increased Noise: An increase in noise during cutting can indicate that the blade is worn out. A sudden and sharp noise is a signal not to be ignored.

4. Cut Quality: When the blade no longer meets quality requirements, producing burrs, uneven finishes, or crooked cuts, sharpening is necessary.

5. Cut Piece Dimensions Out of Tolerance: If the dimensions of the cut piece are no longer precise and fall outside tolerance parameters, the blade needs sharpening.

Specifications for TCT and HSS Blades

• Broken Teeth: The presence of broken teeth is a clear indicator that the blade needs to be replaced or repaired.

• Material Adhering to the Blade Sides: If material is noticed adhering to the sides of the blade, it must be removed, and the blade needs to be sharpened to restore cutting efficiency.

• Chips without Defined Edges: When the produced chips do not have defined edges, it indicates the blade is not cutting correctly and needs sharpening.

• Material Clogging in the Tooth Gaps: If material clogs within the tooth gaps, it is time to sharpen the blade to avoid cutting problems.

• Excessive Tooth Wear: Excessive tooth wear is a clear signal that the blade needs sharpening to maintain cutting quality.

Regular blade maintenance is fundamental for any company operating in the industrial cutting sector. Recognizing wear signs and intervening promptly can make the difference between efficient operation and compromised productivity. At Moreschi s.r.l., we support companies with sharpening and maintenance solutions that ensure maximum efficiency and blade durability.

Choosing the Right Blade: Technical Advice from Moreschi S.r.l.

In the world of industrial cutting, selecting the right tool can make the difference between acceptable performance and excellent production. With our team of technical experts, Moreschi S.r.l. offers personalized consultation services to identify the most suitable blades for our clients’ specific cutting and production needs.

But what crucial information do we need to provide accurate advice?

Knowledge of the Machine: It is essential to understand the type of machine being used: whether the cut is static—single or multiple—or flying with a single or double blade, or if it is orbital. Controllable parameters such as cutting speed and feed rate are fundamental. When choosing a blade, it is also important to know whether it is possible to vary the blade’s diameter, thickness, and tooth number.

Details of the Material to be Cut: Every material has its own peculiarities, from chemical composition to hardness, from tensile strength to dimensions and shape. It is important to know if the blade must cut on the edge or the straight side of the material, if the piece to be cut is hollow or solid, and whether the cut is with or without internal scarf.

Specific Needs of Our Clients: To offer a tailored solution, we need to understand our clients’ production priorities. Is high volume in a short time crucial? Or is a perfect finish the primary concern? Maybe balance between the two? It is also helpful to know if there have been issues with previously used blades or if there are any desired improvements.

With a wide range of options, from blade body to geometry, from cutting thickness to the number of teeth, Moreschi S.r.l. offers a vast selection of tools, including various PVD coatings.

Are you sure that the tool you are currently using is providing the best possible results? With our specialized technical advice, we can help you optimize your cutting operations and improve your productivity.

Getting Ready for Tube Düsseldorf 2024

At MORESCHI Srl, we’re eagerly preparing for an important event – Tube Düsseldorf 2024 This year we will showcase some of our latest innovations and cutting-edge solutions. But that is not all; we’re also focusing on sustainability and environmental responsibility.

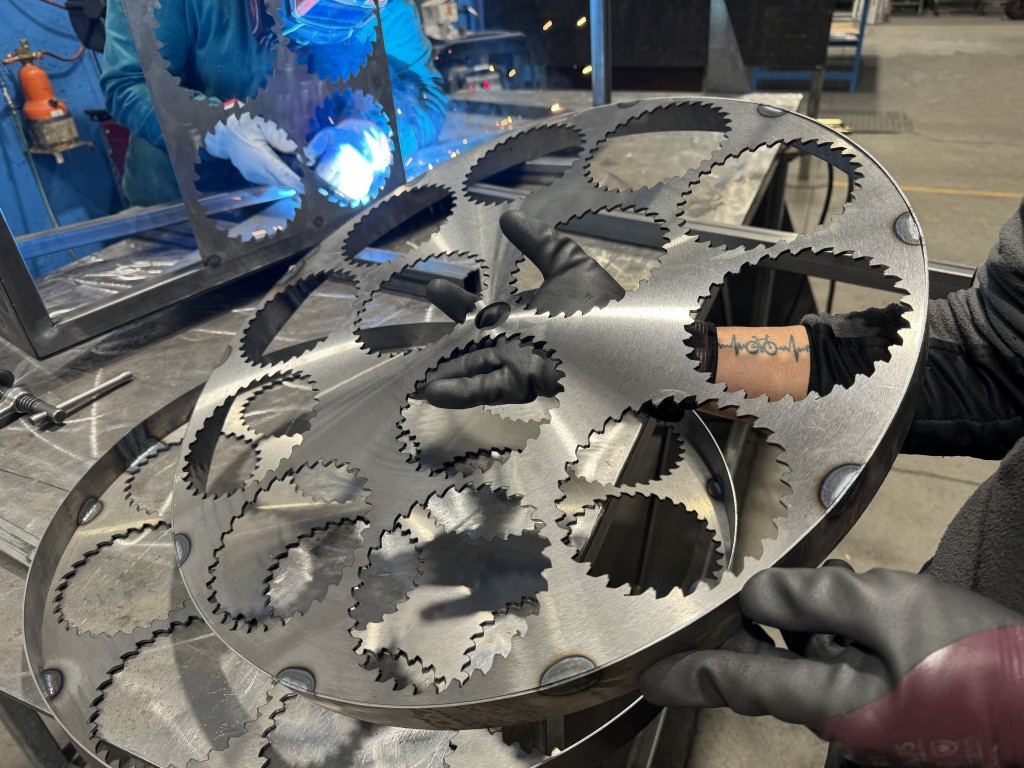

Our booth will be more than just a space to display our products. It will feature furnishings and decorations crafted internally from recycled production waste. From repurposed materials such as metal sheet used in blade cutting, which now adorn our separé, to creatively upcycled table tops, the unconventional design embodies our commitment to sustainability and our dedication to innovation. Please take a look at some of the moments of the preparation.

We invite you to join us at Tube Düsseldorf 2024 at our booth Hall 6/C09.

Nothing left by Chance at Moreschi s.r.l.

Welcome to our inaugural blog post, where we delve into the symbolism behind our logo. While it may seem like a mere visual design at first glance, there’s more to it than meets the eye.

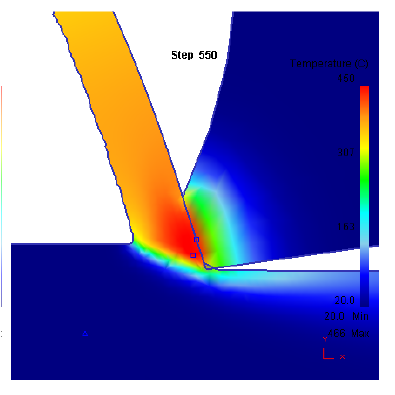

Our logo features our brand name with a distinct figure positioned atop it. This figure symbolizes the shape of a machining chip and boasts a unique chromatic composition spanning from red, orange, yellow, green, to blue.

The colors were meticulously chosen. In the accompanying image, you’ll find an enlarged simulation using FEM 2D (Finite Element Method), depicting a tooth entering a piece of steel. The resulting part breaking off represents the chip, with colors indicating temperatures. Blue denotes room temperature, while red signifies heat at approximately 450°C. Intermediate hues like light blue (163°C) and the transition from green to yellow (307°C) signify temperature variations. Upon zooming in, a vertical color bar reveals areas of heightened heat generation, occurring after approximately 550 steps.

This attention to detail isn’t limited to our logo alone. It extends throughout our production processes, where every aspect is meticulously considered to ensure precision and quality in all that we do.

In the upcoming series of our blog posts, we will cover various topics concerning technical information, maintenance of saw blades, and other curiosities about our company. Stay tuned for more insights!